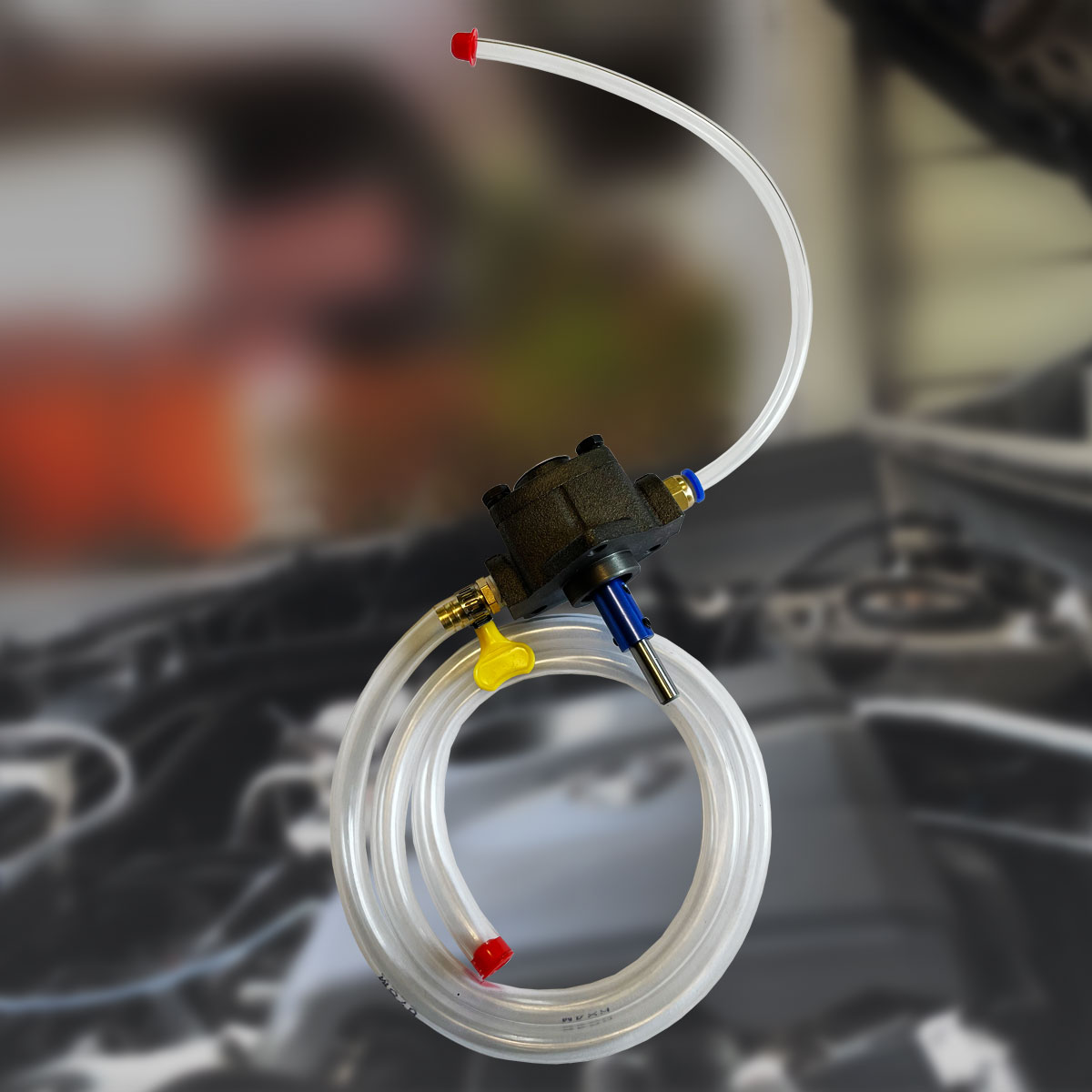

Oil Change Pump Extractor, Oil/Diesel Fluid Pump Extractor Scavenge Oil Change Pump Transfer Suction

A motor vehicle oil pump powered by a power drill makes it easy to change the oil in your vehicle or pump out excess oil.CA$65.00

22% CA$83.00 (21.69%)

Available, delivery time: 2-6 days

Width

Width

Weight

Weight

Product information "Oil Change Pump Extractor, Oil/Diesel Fluid Pump Extractor Scavenge Oil Change Pump Transfer Suction"

Product Introduction

The Electric Drill Oil Extraction Cycloid Pump is designed to extract and add various types of lubricating oils, including engine oil, gear oil, hydraulic oil, and transmission oil. This pump is compatible with both corded and cordless electric drills, making it versatile and convenient for use in small auto repair shops, quick repair shops, transport company fleets, industrial equipment maintenance, and by individual vehicle owners.

Installation Instructions

- Preparation:

- Ensure you have a compatible electric drill. Both corded and rechargeable drills are suitable.

- Ensure the electric drill has a bit with an 8mm diameter round column. A bit with a hexagonal diameter of 8mm to 10mm is recommended. Note that a 6mm bit is not compatible.

- Connecting the Pump

- Attach the pump to the electric drill using the designated shaft and coupling rod.

- Ensure the connection is secure to prevent any detachment during operation.

- Piping and Accessories:

- Select the appropriate fittings and pipes for your application.

- If purchasing as a kit, ensure all components are included and correctly assembled.

Usage Instructions

- Pre-Use Checks:

- Verify that the pump and electric drill are securely connected.

- Ensure the pump is not used for water or any non-lubricating liquids like gasoline, coal oil, alcohol, anti freeze, glass water, urine, agricultural chemicals, glue, paint, or waste oil containing metal particles.

- Operating the Pump:

- Insert the suction pipe into the oil to be extracted or added.

- Turn on the electric drill at a moderate speed to start the extraction or addition process.

- Monitor the flow and ensure there are no leaks or blockages in the piping system.

- Post-Use Care:

- After use, clean the pump and remove any residual oil.

- Store the pump and accessories in a dry place to prevent rust and damage.

Safety Precautions

- Glove Use:

- Always wear gloves when operating the pump to protect your hands from hot oil and potential injury.

- Avoid Non-Lubricating Liquids:

- Do not use the pump for extracting or adding water or non-lubricating liquids. This can damage the pump’s internal steel gears and result in corrosion and failure.

- Temperature and Viscosity:

- Preheat the oil, especially during winter, to ensure smooth operation. Engine oil should be heated to approximately 60°C (140°F) before use.

- Ensure the viscosity of the oil is below 140 for smooth operation. Highly viscous oils may require additional heating.

- Proper Handling:

- Do not operate the pump in an environment with combustible or corrosive substances.

- Ensure all fittings and connections are secure to prevent leaks and spills.

Common Issues and Solutions

- Oil Residue:

- It is normal for new pumps to have residual oil from factory testing. This does not indicate a used product.

- Operating Noise:

- If you hear unusual noises during operation, reduce the speed of the drill and check for any blockages or loose fittings.

- Flow Issues:

- Ensure the oil is adequately heated to reduce viscosity and improve flow rate.

- Use appropriate piping to match the viscosity and temperature of the oil being handled.

By following these instructions and precautions, you can effectively and safely use the Electric Drill Oil Extraction Cycloid Pump for your oil extraction and addition needs.

Login